Subfloor MgO Board

• Strong, durable and very easy to work with regular wood working tools.

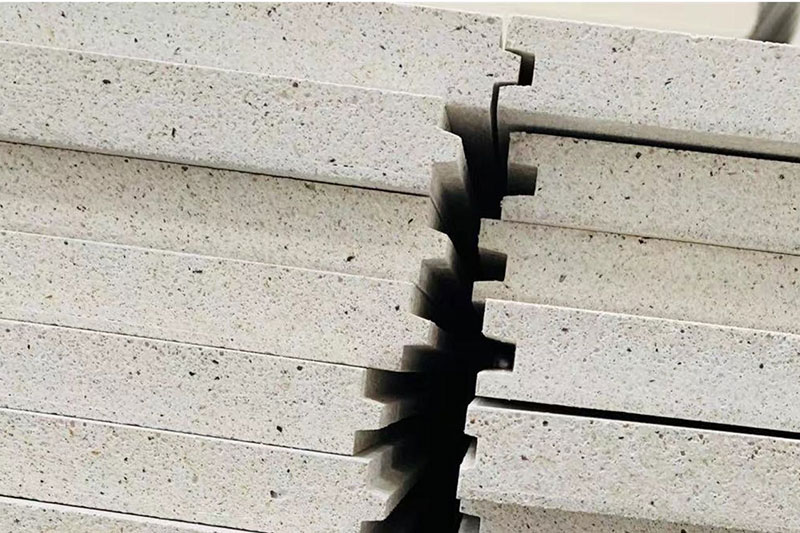

• Dimensionally stable, factory sealed and T&G on long edges or square.

Description

It has the functions of fire, water, mould, sound and heat insulation. Tongue and Groove, Ship-Lap edges available.

| Thickness | Size | Edges | Desnity | Color |

| 16 |

600*2700mm 1220*2440mm | Square, T&G, Shiplap | 1.15kgs/m3 | Off-White, Grey, Black, |

| 18 | ||||

| 19 | ||||

| 20 |

Features

1.Dimensionally Accurate & Stable

Factory sealed with tongue & groove end.

2.Water, Mold & Insect Resistant

Inorganic cementitious materials will not grow mold,Zero nutritional value for complete resistance to termites and all wood-boring insects.

3.Quick & Simple to Install

Worked with regular wood working tools (cuts with a standard carbide tip).

Covered with ceramic tile (with tile backer), hardwood, vinyl or carpet for finished floor.

4.Structural Performance

Structural Non-Combustible building pane, replace traditional plywood or fiber cement board, as the subfloor or underlayment for the Light steel or Timber framing structure buildings.

5.Certified non-corrosive mgo board

Mechanically fastened directly to steel (screwed) or wood (nailed) framing joists.

Application

| Fireproof flooring | Loft flooring | |

| Temporary exhibition flooring | Fireproof assess flooring | |

| Fireproof subfloor | Fireproof resistant roofing | |

| Accessory | Steel frame or timber frame | Power screw driver/ Self drilling screw |

| Structural adhesive | ||

| Limitation | Indoor use | Joist of support 400 – 600mm |

| Can not store outside without tarpaulin |